Table of contents

- Why water in hydraulic oil is an underestimated risk

- How water gets into hydraulic systems - typical causes

- What is the difference between dissolved and free water?

- Damage caused by water in hydraulic oil - these are the consequences

- Effective solution: STAUFF filter elements for water absorption

- How STAUFF filters unfold their full effect

- Proven quality through laboratory tests and practical experience

- STAUFF - your contact for clean hydraulic systems

- FAQs

Why water in hydraulic oil is an underestimated risk

Water in the hydraulic system is an often underestimated damaging factor. It may appear harmless at first glance - but in practice it is responsible for many hidden problems. Corrosion, premature wear or loss of performance are just some of the consequences. Particularly critical: free water that is no longer bound in the oil and is distributed directly in the system.

How water gets into hydraulic systems - typical causes

Water can enter the hydraulic system in various ways:

- Storage: Condensation on drums or in containers

- Maintenance: Open systems, incorrect handling, ambient humidity

- Operation: Leaking seals, inadequate ventilation, temperature fluctuations, cooling water leaks

If the water is not removed at an early stage, it can accumulate in the oil - and even become visible at a certain point - turbidity, milky discolouration or phase separation are typical signs.

What is the difference between dissolved and free water?

Hydraulic oil can "dissolve" water to a certain extent. This dissolved water is invisible and initially unproblematic. The quantity is usually specified in ppm (parts per million) - i.e. milligrams of water per kilogramme of oil.

However, as soon as the so-called saturation point is exceeded (e.g. 300 ppm at 30 °C), the oil can no longer bind any more water. The excess water is then freely present in the system - as droplets or even as a visible phase.

Only free water can be filtered effectively - this is where STAUFF comes in.

Damage caused by water in the hydraulic oil - these are the consequences

Even small amounts of water in the system can cause serious damage:

- Corrosion on components and lines

- Loss of lubrication, which leads to increased abrasion and particle formation

- Destruction of additives in the oil

- Sludge and microbial contamination, especially during shutdowns

- Loss of the oil'selectrical insulation properties

- Risk of ice formation at low temperatures

The following therefore applies: The water content in the oil should always be kept below the saturation point - preferably well below.

Effective solution: STAUFF filter elements for water absorption

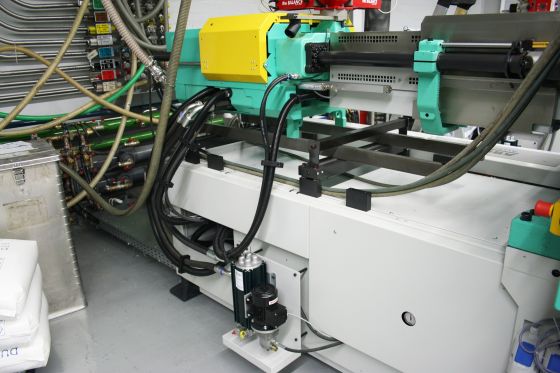

STAUFF filter elements for water absorption have been specially developed to remove free water from the oil in a targeted and permanent manner. At the heart of these filters: a water-absorbing layer of superabsorber, which binds the water and securely traps it, and high-quality glass fibre fleece, which also reliably retains solid particles. The multi-layer structure (including stainless steel wire mesh and support fleece) not only dewaters the oil, but also cleans it.

The filter elements are available in different designs and are preferably used in the bypass and return filter area. On special customer request, pressure filter elements with water-absorbing fleece can also be realised.

Designs are e.g.

- RE return line filter elements and SE pressure filter elements in GA design

- NR-630-EA (for mobile filter systems SMFS)

- SRM-30-EA and SRM-60-EA (for stationary off-line filters OLS/BPS)

Available in 3, 5, 10 and 20 µm filter fineness - depending on the application. Our range also includes type W water-absorbing spin-on filter elements.

This is how STAUFF filters develop their full effect

The following operating conditions should be observed to maximise water absorption performance:

- Install in the bypass flow - for a constant, low flow rate

- Operate at low temperatures - as the water solubility in the oil is lower here

- Avoid large fluctuations in pressure and flow rate

- Keep an eye on the solids load, as this can reduce water absorption

With these tips, you can get the best out of the filter elements - and ensure permanently stable oil quality.

Proven quality through laboratory tests and practical experience

STAUFF filter elements have been extensively tested - beyond the usual standards. They have been proven in special laboratory tests:

- High water absorption over several cycles

- Stable filtration performance despite increasing saturation

- Low differential pressure development, which indicates permanently low energy consumption

The result: reliability, even under demanding conditions.

STAUFF - your partner for clean hydraulic systems

Whether mobile systems, stationary machines or sensitive special applications: STAUFF is at your side as a competent partner when it comes to the reliable removal of water and particles from hydraulic systems.

Do you have questions about the right filter element, the optimum application or do you need technical advice? Our team of experts will be happy to support you - personally and practically. Get in touch now or speak to your local STAUFF contact person!

FAQs

How do I recognise if there is water in the hydraulic oil?

Turbidity, milky discolouration or phase separation are typical signs. Laboratory analyses (e.g. PPM value) provide more precise results.

In addition to determining the PPM value, determining the relative humidity of the hydraulic oil can also provide information about the water content. As with air, the relative humidity indicates the degree to which the oil is already saturated with water. The saturation point 100% then corresponds to the point at which water can be present in free form in the system. Here, the particle counters of the mobile LasPaC series and the stationary LPM series from STAUFF offer optional sensors that fulfil this task

How long does a filter element for water absorption last?

That depends on the water and particle content in the system. STAUFF recommends regularly checking the differential pressure and oil condition.

What exactly does "ppm" mean?

"Parts per million" - in this case milligrams of water per kilogramme of oil. Example: 300 ppm = 0.03 % water content in the oil.

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog